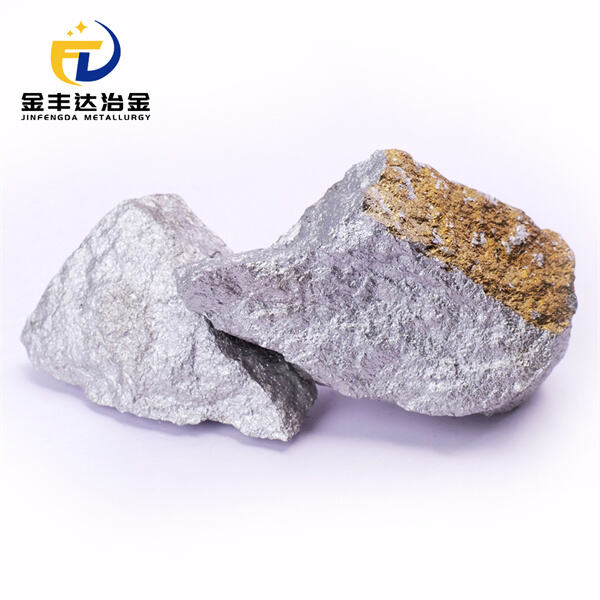

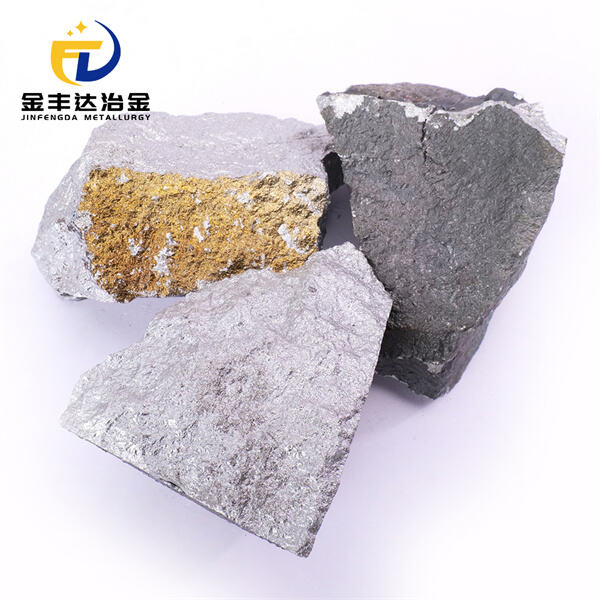

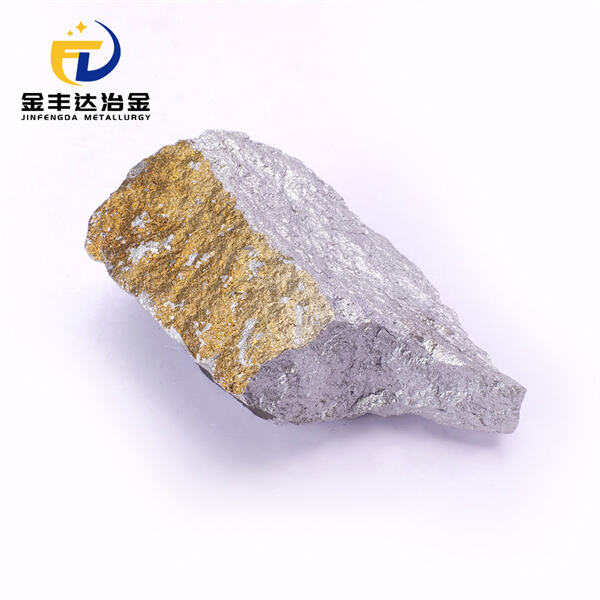

Ferromanganese is the particular kind of alloy which is obtained by combining manganese and iron. Steel is often alloyed with this element to make it stronger and more durable. It is also used to clean the steel by getting rid of unwanted products, so the steel would be a higher quality.

Ferromanganese alloy is indispensable to steel production. When added to steel, it determines the amount of manganese and iron in the steel. This matters because it determines how strong and how long-lasting the steel is. That’s why alloy carbon is a fundamental component when making high quality steel products.

There are many advantages in the use of best quality ferro chrome. It toughens the steel, which makes it stronger and tougher, meaning it can be put to use in many a groovy way. The steel made from this alloy is commonly used in buildings, cars and even everyday household objects. It also prevents rust, which helps the steel last.

Manganese metal is alloyed with iron in ferromanganese to make steel. This blend are melted into the Inconel alloy at high temperatures. The alloy is then itself, once it has cooled, broken into smaller pieces to be added to steel-making. This would have to be done just right, however, to achieve the desired levels of both manganese and iron.

Summary Of The Market The World Ferromanganese Product Market: A Strategic Entry Report, 2000 The World Ferromanganese Product Market-carousel The World Ferromanganese Product Market: A Strategic Entry Report, 2000 You may not have heard of the ferromanganese product market before, but you have certainly heard of the product itself.

World demand is growing for ferromanganese alloy as more people desire high-quality steel products. Among the largest producers of ferromanganese alloy are countries including China, India, and the US. This demand for the alloy is projected to grow as the construction and car sectors expand.

With over 20 years of export experience, we have successfully served markets in South Korea, Japan, Germany, Turkey, Russia, and beyond, providing timely delivery, strong logistics partnerships, and reliable after-sales support.

Our 120,000-square-meter factory is equipped with 26,300KVA alloy refining electric furnaces and 8 intermediate frequency furnaces, ensuring robust production capabilities for a variety of metallurgical products including Ferro Silicon and Low Carbon Ferro Chrome.

We implement stringent quality control through in-house element testing and support third-party inspections (SGS, BV, AHK), ensuring our products meet international standards for purity and performance.

We offer personalized metallurgical solutions tailored to client needs, backed by a 1-hour response guarantee via multiple channels (WhatsApp, WeChat, Email) and dedicated problem-solving throughout the project lifecycle.