Ferromanganese is a type of metal that is really important in creating steel! It strengthens the steel and makes it last longer. Today, we are going to find out how ferromanganese is produced and why it’s so crucial in making steel.

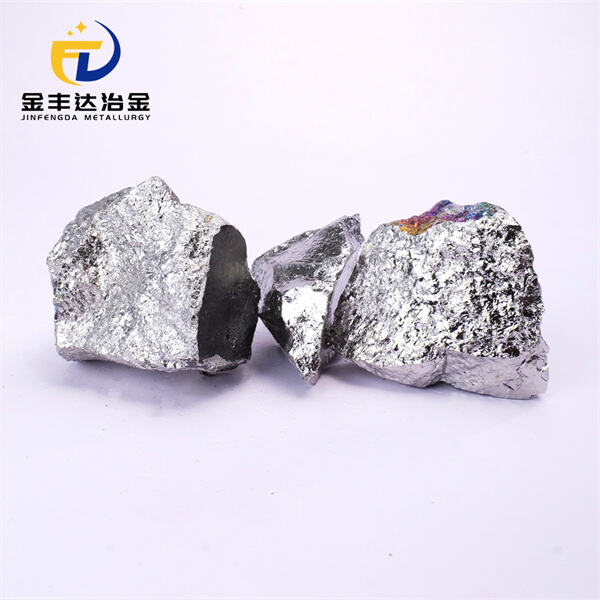

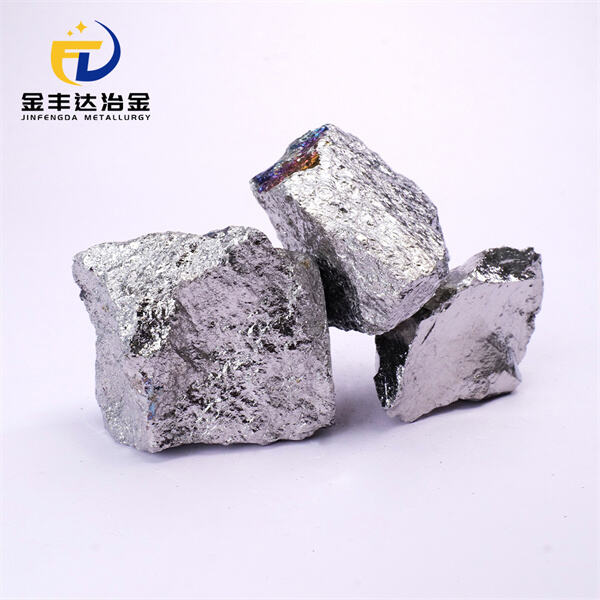

Ferromanganese is produced by mixing two main ingredients: manganese ore and iron ore. This combination of the ingredients are melted together in a large kitchen style furnace. This is known as the smelting. Once the ferromanganese forms, it cools down and fractures into pieces. These are known as ferromanganese alloys.

Ferromanganese is indispensable in the produc- tion of steel. Steel is used to build lots of things we use every day, including cars, buildings and appliances. Steel wouldn’t be able to withstand as much without ferromanganese. Steelmakers add ferromanganese to steel to create different types of steel for special purposes, such as construction or machines.

Ferromanganese is also crucial for steel, but its production can damage the environment. The smelting process also spews a great deal of carbon dioxide and other damaging gases into the atmosphere. To make ferromanganese in a cleaner and more environmentally friendly process, companies like Jinfengda are striving. This site uses some renewable energy and has measures to recycle more.

The demand for ferromanganese will increase as more steel is required. This poses opportunities and challenges for the ferromanganese sector. Trend number one: develop new technology approaches to make the production process more efficient and environmentally friendly. “But there are challenges including pricing of materials that vary and competition from other materials. Enterprises such as Jinfendga are always searching for ways to overcome these obstacles and work towards a better future in the production of ferromanganese.

With over 20 years of export experience, we have successfully served markets in South Korea, Japan, Germany, Turkey, Russia, and beyond, providing timely delivery, strong logistics partnerships, and reliable after-sales support.

We offer personalized metallurgical solutions tailored to client needs, backed by a 1-hour response guarantee via multiple channels (WhatsApp, WeChat, Email) and dedicated problem-solving throughout the project lifecycle.

Our 120,000-square-meter factory is equipped with 26,300KVA alloy refining electric furnaces and 8 intermediate frequency furnaces, ensuring robust production capabilities for a variety of metallurgical products including Ferro Silicon and Low Carbon Ferro Chrome.

We implement stringent quality control through in-house element testing and support third-party inspections (SGS, BV, AHK), ensuring our products meet international standards for purity and performance.