The material, Ferrosilicon 75, is what allows steel to be stronger, better. It strengthens metal and makes it last longer. It also aids in preventing materials like iron from being damaged by rust and heat. Jinfengda belongs to a company that merely produces ferrosilicon 75 and uses ferrosilicon plant to make great products.

Steel is a strong metal it is for lots of things cars, buildings, and tools. Ferrosilicon 75 is sort of the secret sauce that makes steel extra tough. It is combined with other elements to form an alloy that is strong and durable — making steel. Strong steel is used to build things that must be dependable.

Metal casting is the process in which molten metal is poured into a mold to create a shape. The finished products quality can be improved by using Jinfengda 75 ferrosilicon. It assists the metal in smoothly flowing into the mold, creating better metal parts. This is an indication that metal products produced with buy ferrosilicon are of good quality and good usability.

Iron may be tough stuff, but it breaks or wears out eventually. Producers can make iron products even stronger object by adding ferrosilicon 75. The alloy strengthens the structure of iron, making it harder and less likely to bend or break. As a result, iron products made with ferrosilicon powder will last longer and can withstand more use.

Corrosion is the process that causes metal, such as iron, to rust and deteriorate. Heat can also harm metals. Ferrosilicon 75 can also help in preventing such damage by over coating the metal with a protection skin. It is this layer that protects the metal from things that can damage it. This is because ferrosilicon production products are rust and heat resistant; and they last longer.

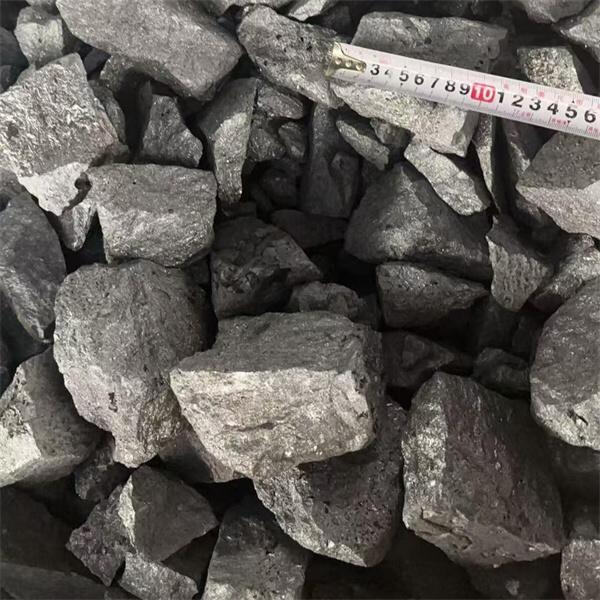

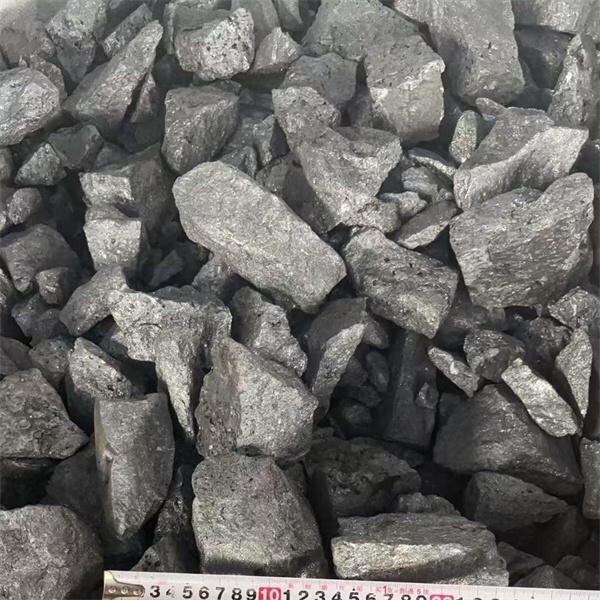

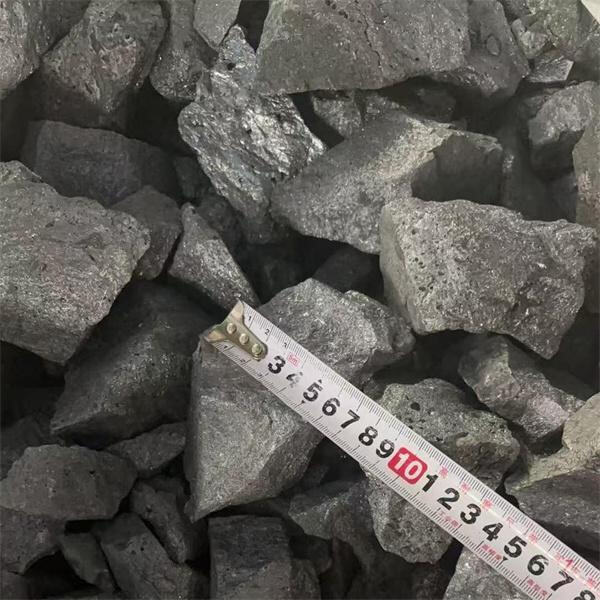

Ferrosilicon 75 is produced by the addition of other elements in special proportion. This is an alloy with the right combination of ingredients to be strong. Jinfengda applies machines and technique to produce excellent ferrosilicon 75 alloy. Through careful process control from raw vats to finished batches, it makes the alloys good as new for reuse in various applications.

With over 20 years of export experience, we have successfully served markets in South Korea, Japan, Germany, Turkey, Russia, and beyond, providing timely delivery, strong logistics partnerships, and reliable after-sales support.

We implement stringent quality control through in-house element testing and support third-party inspections (SGS, BV, AHK), ensuring our products meet international standards for purity and performance.

Our 120,000-square-meter factory is equipped with 26,300KVA alloy refining electric furnaces and 8 intermediate frequency furnaces, ensuring robust production capabilities for a variety of metallurgical products including Ferro Silicon and Low Carbon Ferro Chrome.

We offer personalized metallurgical solutions tailored to client needs, backed by a 1-hour response guarantee via multiple channels (WhatsApp, WeChat, Email) and dedicated problem-solving throughout the project lifecycle.