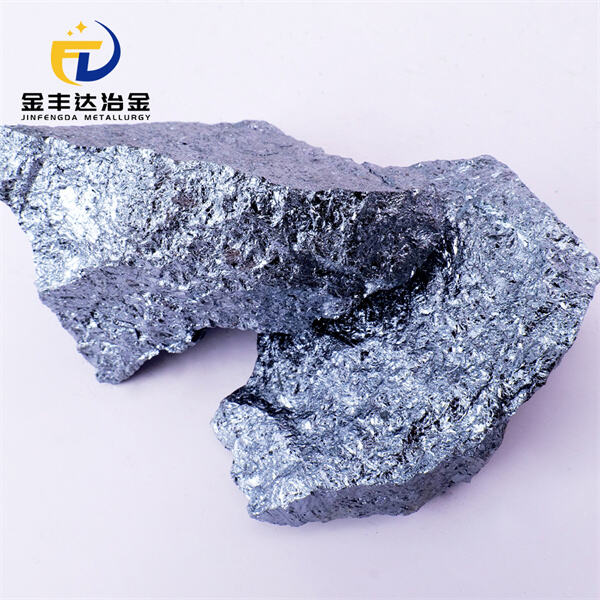

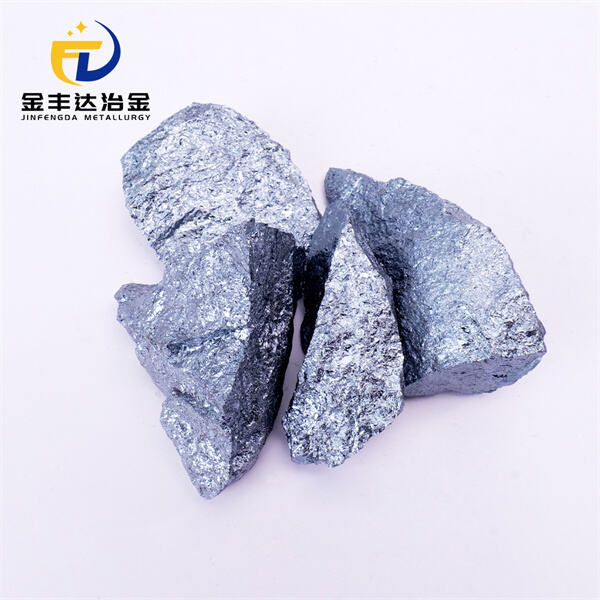

Metallic silicon is a shiny, silvery metal that has a lot of cool properties. It is highly useful and applicable to a wide range of industries. So let’s take a trip to alloy carbon and discover all the amazing things metallic silicon can do!

Metallic silicon possesses unique properties that make it favorable for myriad applications. It is an excellent conductor of electricity, so it helps things like phones, computers and tablets function. Metallic silicon is also durable and long lasting, so it is a good material for constructing objects that have to be sturdy.

For manufacturing electronics, best quality ferro chrome is crucial for making those little chips and circuits that run our electronics. These chips are produced using a technique referred to as silicon wafer fabrication, in which thin slices of raw, metallic silicon are layered with various other materials to form patterns necessary for electronics to function. Our electronics would not be as effective without metallic silicon.

We see even more potential uses when we consider how metalic silicon is used in solar energy. Metallic silicon is a necessary ingredient in solar panels that capture sunlight and turn it into energy. We can make clean energy that is made by the sun and helps us use less fossil fuels. Metallic silicon is ideal for solar panels because it does an excellent job of absorbing sunlight and converting it into electricity.

There is also a high demand of metal silicon in the sector of automobiles. It is used to produce car parts such as engine blocks, pistons and wheels. Its durability also makes it an excellent material for building cars that are safe and durable and withstand high frequency use. And it also has applications in electric cars, helping to power the batteries that allow such cars to run on electricity rather than gasoline.

Metallic silicon alloys have given rise to some even more interesting possibilities. This metallic silicon can be alloyed with other metals to produce special-purpose alloys. For instance, mixing steel with metallic silicon makes it stronger and less prone to rust. This matters quite a bit in construction, where we want materials that will endure. We will be able to find new applications in many areas if we continue to develop highly innovative metallic silicon alloys.

We offer personalized metallurgical solutions tailored to client needs, backed by a 1-hour response guarantee via multiple channels (WhatsApp, WeChat, Email) and dedicated problem-solving throughout the project lifecycle.

Our 120,000-square-meter factory is equipped with 26,300KVA alloy refining electric furnaces and 8 intermediate frequency furnaces, ensuring robust production capabilities for a variety of metallurgical products including Ferro Silicon and Low Carbon Ferro Chrome.

We implement stringent quality control through in-house element testing and support third-party inspections (SGS, BV, AHK), ensuring our products meet international standards for purity and performance.

With over 20 years of export experience, we have successfully served markets in South Korea, Japan, Germany, Turkey, Russia, and beyond, providing timely delivery, strong logistics partnerships, and reliable after-sales support.