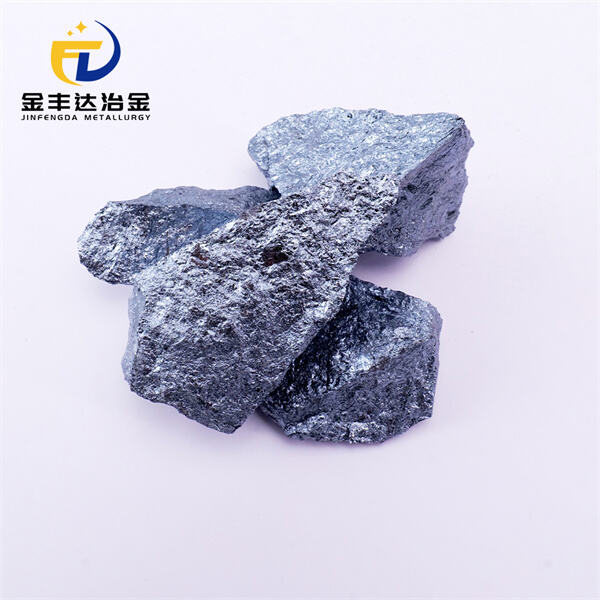

Metallurgical silicon, a special and high-value material used to produce all kinds of things, including steel. It is useful for many products and it makes them stronger and more enduring. Let’s get to know refractory and metallurgical solutions and why it is unique. Metallurgical silicon is also a bright and hard metal. It can withstand high temperatures and pressure, which is why it is so good for making steel. Steel has to be strong and durable. Metallurgical-grade silicon is also used to make other types of metal, including that of aluminum and copper. Due to some special properties, It is one of the most frequently used components in a lot of manufacturing processes.

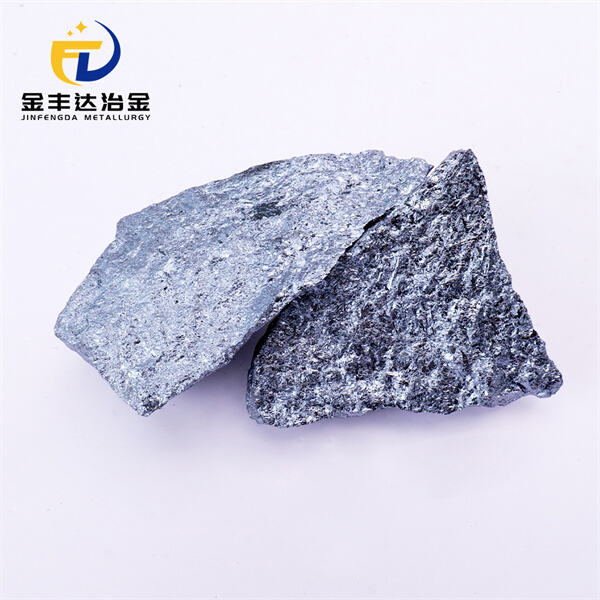

In the steel industry, metallurgic silicon is used. Steel is employed in numerous everyday products, including cars, buildings and appliances. Incorporating metallurgical silicon into steel makes it stronger, and last longer. It’s what enables steel to last even under heavy use. Metallurgical silicon allows steel to be strong and dependable.

High purity is essential in the production of Metallurgical grade silicon. Before cleaning, any contaminants must be eliminated from the metal. Such impurities can weaken and degrade the effectiveness of the metal. Jinfengda Ferro Silicon attaches great importance to the purity of its metallurgical silicon, the high standard of which our customer needs for the production of the steel and other industries.

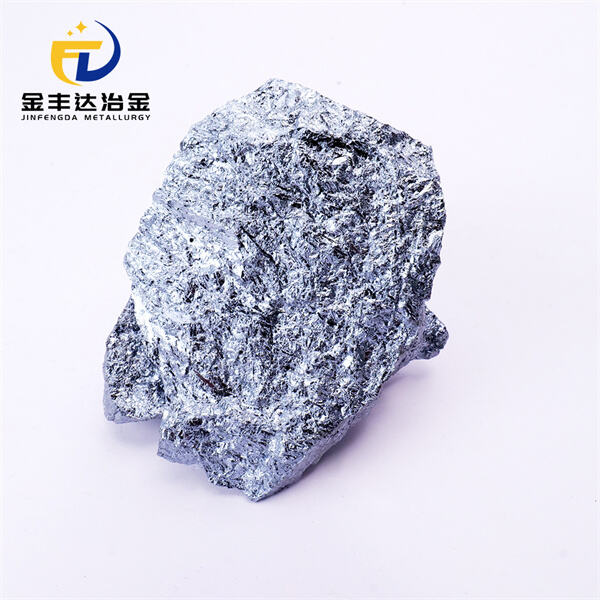

Recent advances in metallurgical silicon technology make it feasible to produce high-quality metal. Novel approaches and tools in the metallurgical treatment of silicon are introduced to purify silicon and to harden same. "Heavy industrial projects like Jinfengda Ferro chrome benefit from such upgrades and the global increasing demand for metallurgical silicon." By using better technology, we are able to make metallurgical silicon better, and find new ways to use it in industry.

Metallurgical silicon also strengthens other materials when added to them. This can be particularly beneficial for construction and transportation, where materials must stand up to harsh conditions. Jinfengda Silicon metal are constantly researching new applications for metallurgical silicon in order to enhance their productqualityanddurability.

With over 20 years of export experience, we have successfully served markets in South Korea, Japan, Germany, Turkey, Russia, and beyond, providing timely delivery, strong logistics partnerships, and reliable after-sales support.

We implement stringent quality control through in-house element testing and support third-party inspections (SGS, BV, AHK), ensuring our products meet international standards for purity and performance.

Our 120,000-square-meter factory is equipped with 26,300KVA alloy refining electric furnaces and 8 intermediate frequency furnaces, ensuring robust production capabilities for a variety of metallurgical products including Ferro Silicon and Low Carbon Ferro Chrome.

We offer personalized metallurgical solutions tailored to client needs, backed by a 1-hour response guarantee via multiple channels (WhatsApp, WeChat, Email) and dedicated problem-solving throughout the project lifecycle.