We frequently hear when discussing metals like the ferro silicon, how we can alloy them with different elements to make them stronger or more durable. One of such elements is silicon. Silicon is a shiny, grey metal that is commonly used to make metal alloys. When silicon is mixed with metals like iron or aluminum it can alter the characteristics of the metal and enhance its usefulness for particular purposes.

Metal casting is a technique that has been in use for made years. When the metal is spiked with silicon prior to casting it can increase the metal’s fluidity facilitating the filling of the mold. The latter can lead to improved castings having minimal defect. Silicon like the silicon ferro may also help to keep the metal from shrinking as it cools which can result in final products that are more accurate and precise.

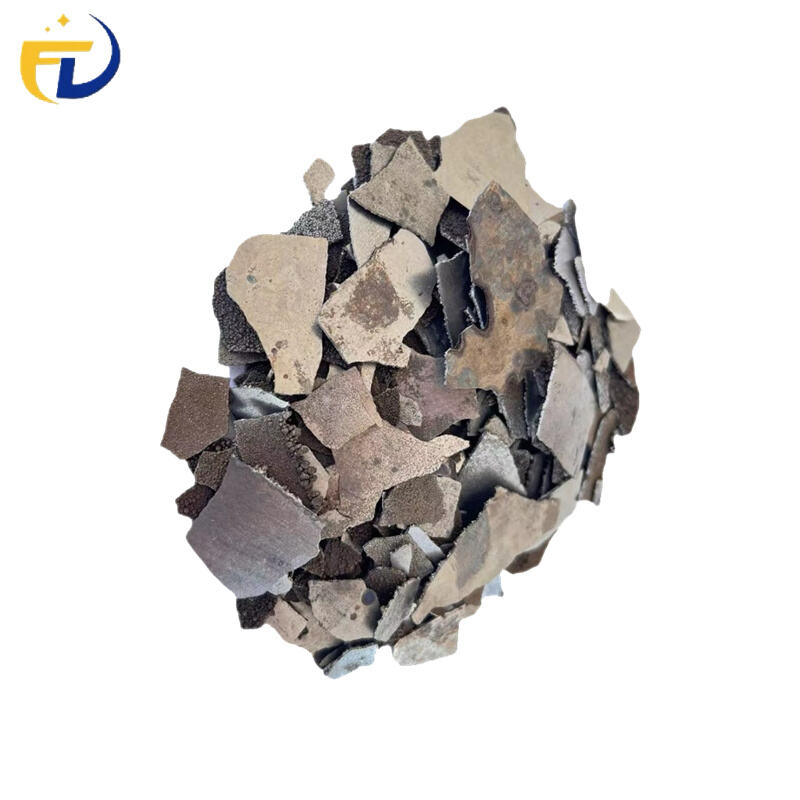

To Increase Strength and Durability of a ferro silicon One of the most significant purposes of adding silicon to metal alloys is to increase their strength and durability. Silicon is used to make metals such as steel harder and more resistant to wear and corrosion and this is of particular importance in applications in which the metal may be exposed to high temperatures or severe environments. Silicon added to the metal can allow manufacturers to produce products that will last longer and perform better.

Siliconized metals like the ferro silicon powder can be used in a variety of applications at various industries. In the automotive sector silicon enriched steel is applied to produce engine components that are required to bear high temperatures and pressures. Silicon aluminum is also used in building materials to achieve a lighter but stronger product in the building industry. In the electronics industry silicon copper is employed to produce wires and connectors capable of conducting electricity more efficiently. Hybridized metal with silicon is suited for many applications.

With the development of science and technology the application of silicon like the ferro silicon alloy in the field of metallurgy is expanding. From items from outer space to next generation body armour, inventors and manufacturers are always looking for ways to put silicon in metal to make stronger, lighter and harder products. Whether in aerospace healthcare or manufacturing the potential for silicone infused metals is vast. With companies such as Jinfengda at the forefront of new technologies the future of silicon in metals production is looking promising.

We implement stringent quality control through in-house element testing and support third-party inspections (SGS, BV, AHK), ensuring our products meet international standards for purity and performance.

Our 120,000-square-meter factory is equipped with 26,300KVA alloy refining electric furnaces and 8 intermediate frequency furnaces, ensuring robust production capabilities for a variety of metallurgical products including Ferro Silicon and Low Carbon Ferro Chrome.

We offer personalized metallurgical solutions tailored to client needs, backed by a 1-hour response guarantee via multiple channels (WhatsApp, WeChat, Email) and dedicated problem-solving throughout the project lifecycle.

With over 20 years of export experience, we have successfully served markets in South Korea, Japan, Germany, Turkey, Russia, and beyond, providing timely delivery, strong logistics partnerships, and reliable after-sales support.