Jinfengda is an established enterprise in metallurgic refractory industry devoting to the production of necessary alloy such as Ferro Silicon; Low Carbon ferro Chrome and Metal Silicon. Founded in 2018, Jinfengda is dedicated to offering world-class products and services for global users. Equipped with the most advanced stainless steel-making facilities like 1×26,300KVA AOD refining furnace and 8 intermediate-frequency furnaces, Jinfengda has standardized and effective production process as well as perfect quality control system to ensure best product quality. “It’s not only in Indonesia, we direct export because they know that if we say the product is like this, it's really like that,” Hermawan added. The company's commitment to integrity, responsibility, innovation and superb service has gained it recognition as a reliable supplier of countries such as South Korea, Japan and Germany.

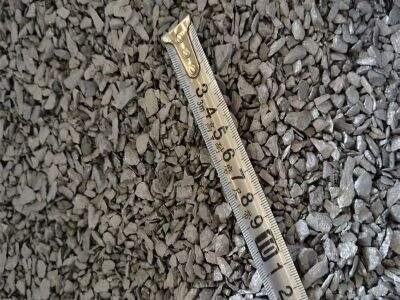

Ferro chromium reinforcing the strength of stainless steel

When it comes to stainless steel production ferro chromium is a significant addition to increase the strains and reduce the brittleness of the final product. The tensile strength and durability of the steel alloy is considerably elevated by incorporation of ferro chromium to a composition for its manufacture. So it can be inferred that low carbon ferro chromes containing ferro chrome have higher load-bearing capacity and are more resistant to unfavorable weather conditions under stress. This increased toughness is of particular significance for construction, automobile and aerospace industries where strength and durability are crucial.

The role of ferro chrome on the corrosion resistance stainless steel

The great benefit of using ferro chromium for stainless steel production is improving the corrosion resistance properties in the steel. Stainless steel is an iron alloy with resistance to staining and rusting in many environments. This resistance is even further enhanced by the addition of ferro chromium to the alloy, which helps maintain its integrity and prevents it from corroding in more rugged surroundings. This is crucial for maintaining the durability and looks of stainless steel products in time.

Relative importances of ferro chromium in producing a fine finish to stainless steel products

As well as strengthening and corrosion resistance, ferro chromium is a key ingredient in enhancing the surface quality of stainless steel products. The addition of ferro chromium to the alloy creates a more glossy finish that looks cool and feels great. This is important when it comes to manufacturing industries that require a real-life look of the final product like architecture, interior design and kitchenware. With the addition of ferro chromium, ferro chrome alloy have an outstanding finish that meets even strict and high-quality requirements.

The sheer ability property of corn straw in this study

Yet another important advantage of ferro chromium usage in the production of stainless steel, is its capacity to improve considerably this material's weldability. Weldability is the ability of a material to be welded without important defects. Adding ferro chromium to the alloy is the means by which manufacturers find it possible to achieve a more desirable stainless steel that can be welded, and therefore shaped and formed for fabrication purposes. This makes it possible to effectively assemble and weld stainless steel products, to obtain sound and reliable structures.

The most important ingredient for long life of a stainless steel building

Finally, ferro chromium is an essential component for extending the life span of facilities made out of stainless steel. Ferro chromium enhances the strength, corrosion resistance and finish and quality of materials allowing stainless steel products to remain a lasting resource. Whether for buildings, ships, industrial equipment or household appliances, stainless steel products produced with ferro chromium are stronger and more durable. This type of longevity is not only good for manufacturers and consumers by lowering maintenance and replacement costs, but also represents an eco-friendly standpoint in durable manufacturing.

Conclusion

neither can the importance of ferro chromium in making ferro manganese overemphasized. With thicker core gauges, it cuts harder and is resistant to tearing. Created with t Endeaching or temper passing Endto add ductility. Ferro chrome ferro hromium one of the most important ir elements in stainless steel.

Table of Contents

- Ferro chromium reinforcing the strength of stainless steel

- The role of ferro chrome on the corrosion resistance stainless steel

- Relative importances of ferro chromium in producing a fine finish to stainless steel products

- The sheer ability property of corn straw in this study

- The most important ingredient for long life of a stainless steel building

- Conclusion