Silicon carbide is a special material which is very useful in the production of many of the things we use on a daily basis. So what makes silicon carbide so special and just what’s the big deal with this larger grain?

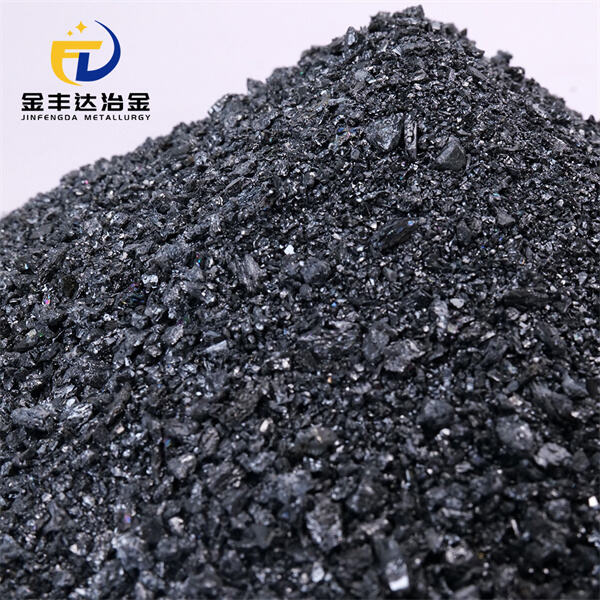

Silicon carbide by Jinfengda is a very hard and sharp material. It’s able to withstand high temperatures and hard use. It is used to make cutting tools, grinding wheels, and even armor for military vehicles. This is due to carborundum silicon carbide's being a highly durable material that does not rust like steel.

It is manufactured by mixing silicon with carbon and heating it in a high-temperature oven. The mixture becomes extremely hot until crystals of Silicon Carbide form. These crystals are crushed into smaller pieces. These tiny things can be used to produce a variety of products – from electronics to machines.

Silicon carbide is fundamental to several modern technologies. It makes semiconductors, which are required for electronics such as computers and smart phones. Silicon carbide may also be known in power electronics, helping devices perform better and last longer. This renders it a crucial candidate for future technology.

Many industries are changing the way things are done with silicon carbide. For instance, in cars, silicon carbide makes some electrical systems more efficient and others more powerful. And in the realm of energy, Silicon Carbon Alloy is aiding in the shift to sustainable renewable power generating systems such as solar and wind power. So all in all, silicon carbide is powering an ever more seamless world.

Silicon carbide is super sustainable, which is great. Since it is so strong and that it has a very long life, anything made of silicon carbide can last for a few decades without having to replace it. This controls waste and saves resources. Plus, Jinfengda silicon carbide is efficient, helping us do more with the energy resources we have, and contributing to our efforts to reduce our environmental impact.

We implement stringent quality control through in-house element testing and support third-party inspections (SGS, BV, AHK), ensuring our products meet international standards for purity and performance.

With over 20 years of export experience, we have successfully served markets in South Korea, Japan, Germany, Turkey, Russia, and beyond, providing timely delivery, strong logistics partnerships, and reliable after-sales support.

Our 120,000-square-meter factory is equipped with 26,300KVA alloy refining electric furnaces and 8 intermediate frequency furnaces, ensuring robust production capabilities for a variety of metallurgical products including Ferro Silicon and Low Carbon Ferro Chrome.

We offer personalized metallurgical solutions tailored to client needs, backed by a 1-hour response guarantee via multiple channels (WhatsApp, WeChat, Email) and dedicated problem-solving throughout the project lifecycle.