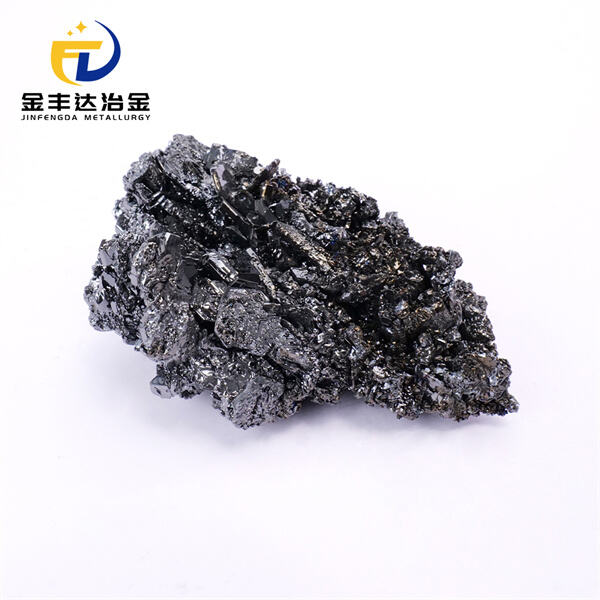

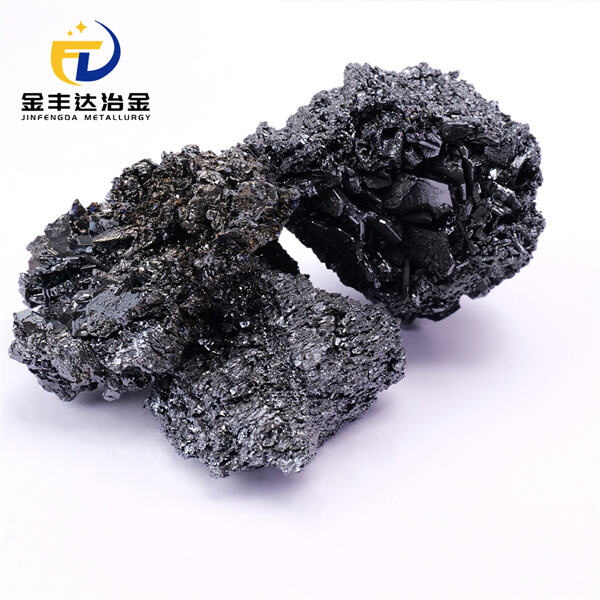

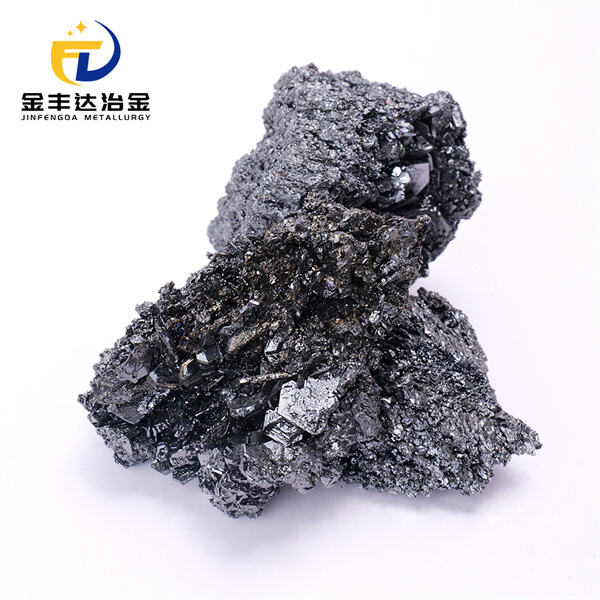

Silicon carborundum is a very neat material with all sorts of special properties. It is composed of silicon and carbon, both elements listed in the periodic table. Carborundum is extremely hard and strong, and very useful for a great many purposes. Deduciamos sobre este maravilloso material. One of the reasons Silicon Metal is so special is its hardness. It’s one of the hardest substances in the world, harder than diamonds. This hardness also makes it ideal for cutting, grinding and polishing other materials. Picture being able to cut through metal effortlessly—that’s the kind of strength silicon carborundum has.

Yet another remarkable feature of silicon carborundum is that it can conduct electricity. This makes it suitable for use in electronic devices that must function properly. You will also notice that silicon carborundum is great in heat resistance and can resist high temperatures, which makes it ideal for hot places such as factories. It can resist temperatures as high as 2700 ° C. Silicon carborundum is of the utmost value in technology. It’s employed in the manufacturing of computer chips — the brains behind our electronic devices. Without silicon carborundum, we wouldn’t have smartphones, laptops and other gadgets that help us in our daily lives.

Silicon carborundum is also used in the production of solar panels, not just in electronics. Solar energy, solar panelsSolar panels allow us to harness the power of the sun to produce clean energy. By making solar panels out off ferro silicon, we could make them better and cheaper for all.

Silicon carborundum other than for technology and industry has many uses. It is used to produce ceramic materials, which are used in everything from pottery and tiles to dental implants. Silicon Carbon Alloy is durable to a farden heat, and may be used to a great advantage in the making of strong and handsome pottery.

Silicon carborundum is used to make grinding wheels, whet steel, saws and drill bits. With its durability and long-lasting sharpness, it is ideal for cutting metal and concrete, among other difficult materials. With calcium silicon tools, the worker can work faster and better.

We offer personalized metallurgical solutions tailored to client needs, backed by a 1-hour response guarantee via multiple channels (WhatsApp, WeChat, Email) and dedicated problem-solving throughout the project lifecycle.

Our 120,000-square-meter factory is equipped with 26,300KVA alloy refining electric furnaces and 8 intermediate frequency furnaces, ensuring robust production capabilities for a variety of metallurgical products including Ferro Silicon and Low Carbon Ferro Chrome.

With over 20 years of export experience, we have successfully served markets in South Korea, Japan, Germany, Turkey, Russia, and beyond, providing timely delivery, strong logistics partnerships, and reliable after-sales support.

We implement stringent quality control through in-house element testing and support third-party inspections (SGS, BV, AHK), ensuring our products meet international standards for purity and performance.