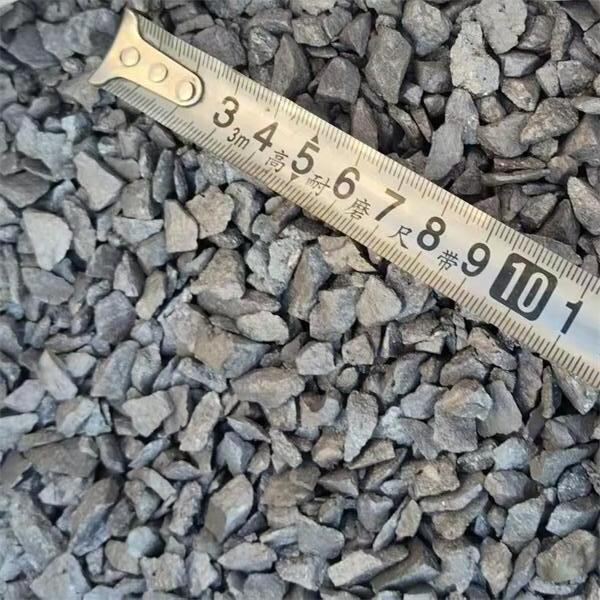

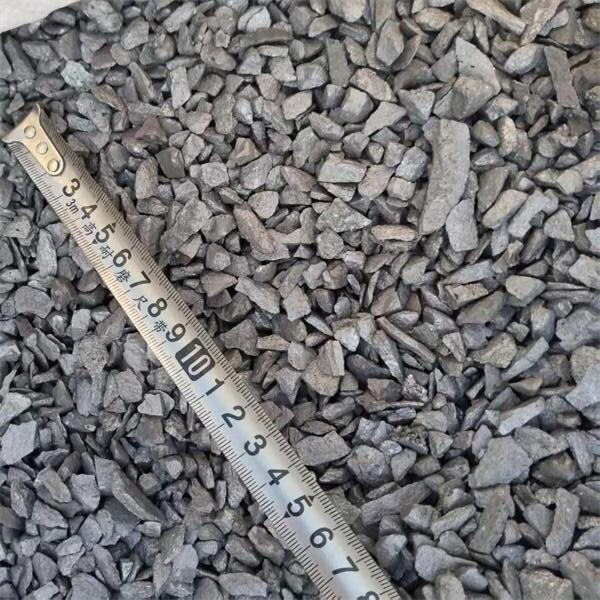

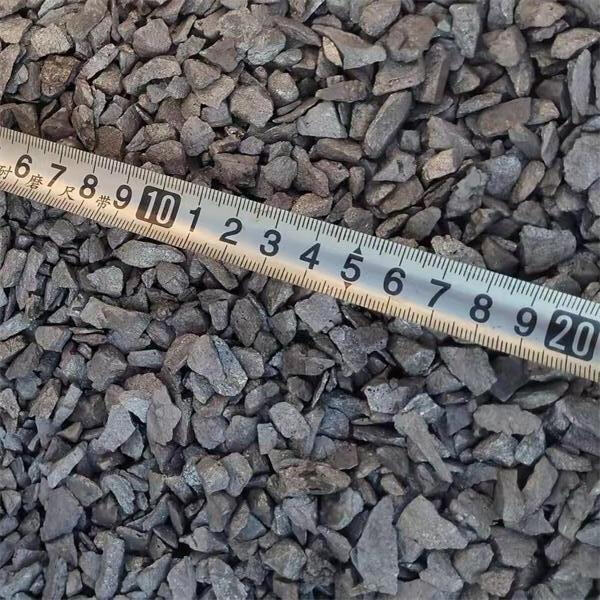

The ferro silicon granule is actually grains in size, and it is a unique type of minerals that do wonders for today's growing industries. They can be used as they are not used before that make products strong and better; well here in this article we get to learn about how are these ferro silicon granules used, and what they are so important about?

Steel is produced when iron is combined with other metals such as ferro silicon granules. Ferro silicon granules are used to increase and strengthen the steel. This is significant because steel is found in a lot of things that need to be strong, such as buildings and machines. Without ferro silicon granules the steel we have would not be as brilliant or as safe.

In plants that make things, ferro silicon granules have a significant role in contributing towards the making of a great product. They are employed in creating varying forms of steel and metal alloys, which are materials that are formed by combining metals. Ferro silicon granules also contribute to enhancing the characteristics of these materials, so that they are more suitable for all the different types of uses there are.

Ferro silicon granules, it is said, are just like little friends that make iron and steel better in a number of ways. They can help make the materials stronger, harder and less likely to rust or corrode. That means that iron and steel with ferro silicon granules in it can last longer and do more than those without it.

Welcome To The World Of Metals And Minerals Ferro Silicon granules is something that are treated as a part of the most significant creatures of nature. They find use in a vast number of processes that produce new materials and products. If we didn't have ferro silicon lumps, the strong and sturdy material we have would be a lot harder to create.

We offer personalized metallurgical solutions tailored to client needs, backed by a 1-hour response guarantee via multiple channels (WhatsApp, WeChat, Email) and dedicated problem-solving throughout the project lifecycle.

We implement stringent quality control through in-house element testing and support third-party inspections (SGS, BV, AHK), ensuring our products meet international standards for purity and performance.

Our 120,000-square-meter factory is equipped with 26,300KVA alloy refining electric furnaces and 8 intermediate frequency furnaces, ensuring robust production capabilities for a variety of metallurgical products including Ferro Silicon and Low Carbon Ferro Chrome.

With over 20 years of export experience, we have successfully served markets in South Korea, Japan, Germany, Turkey, Russia, and beyond, providing timely delivery, strong logistics partnerships, and reliable after-sales support.