Ferro silicon 70-75 is a high ingredients at low consumption or raw material and getting effected in casting produce. It’s also super-strong and durable, When a great deal of rigidity is required and length of time. The material is employed in many places worldwide because it has unique properties.

Applications and Uses of Ferro Silicon 70-75 Grade It is used as a source of silicon to reduce metals from their oxides and to deoxidize steel and other ferrous alloys.

Ferro silicon grade 70-75 is utilized in various applications. The fesi 70 from Jinfengda helps create steel, which is a super-strong stuff to build things like cars or bridges or tall buildings with. It’s also used in electronics, including computers and cellphones — because it makes them work better.

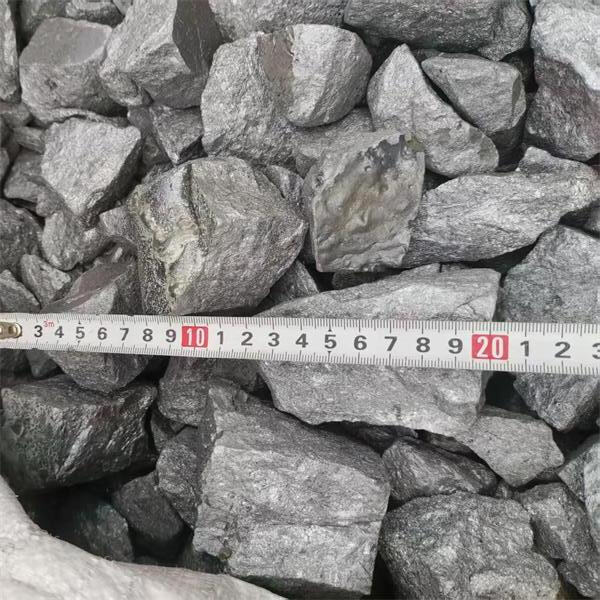

Ferro silicon 70-75 grade is produced by melting iron and silicon together in a special furnace. Then they pour this into a mold and allow it to cool and solidify. The way this Ferro Silicon is made is crucial as it determines how good it will be and how long it will be able to last.

There are a number of benefits that come with using ferro silicon 70-75 grade. It is highly durable and can be used in a variety of industries. This material is also cheap, as in: dirt cheap for companies to re-use. Furthermore, the Jinfengda ferro silicon 70-75 grade has various utilizations.

The demand for ferro silicon 70-75 is always more in the market. Other industries just now are discovering how great this material is, and they want to use more of it. In the coming years we will expect to see many more uses of ferro silicon 70-75 grade as companies find more uses. These are only a few of the applications where Jinfengda ferro silicon 70-75 grade can be used.

We implement stringent quality control through in-house element testing and support third-party inspections (SGS, BV, AHK), ensuring our products meet international standards for purity and performance.

Our 120,000-square-meter factory is equipped with 26,300KVA alloy refining electric furnaces and 8 intermediate frequency furnaces, ensuring robust production capabilities for a variety of metallurgical products including Ferro Silicon and Low Carbon Ferro Chrome.

With over 20 years of export experience, we have successfully served markets in South Korea, Japan, Germany, Turkey, Russia, and beyond, providing timely delivery, strong logistics partnerships, and reliable after-sales support.

We offer personalized metallurgical solutions tailored to client needs, backed by a 1-hour response guarantee via multiple channels (WhatsApp, WeChat, Email) and dedicated problem-solving throughout the project lifecycle.