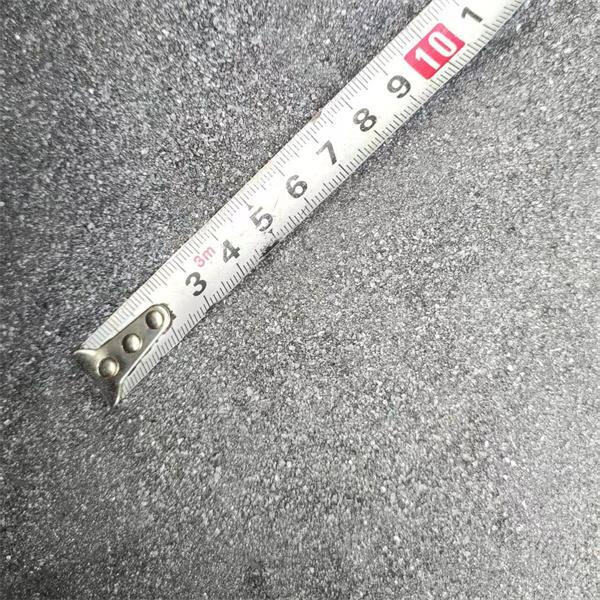

Granules of ferro-silicon is a special type of material to produce strong metal products. They make the metal better and stronger. These amazing Jinfengda Ferro Silicon and we are going to find out what these are used for in different scenarios, today.

Steel is a sturdy metal that goes in buildings, cars and lots of other things. Very important of ferro silicon granules used in steel making. They dig out the metal, cleaning and strengthening it by selecting for the good and against the bad. Jinfengda's ferro silicon granules of high quality used by steel plants from all over the world in producing the fine steel.

Cast iron is a type of metal that is used to make things like cookware and pipes. Ferro silicon granules assist in making the cast iron stronger and durable. And when we get these tiny granules into the metal, they are better able to resist heat and wear. The casting industry has been using their top grade ferro silicon granules because they're great.

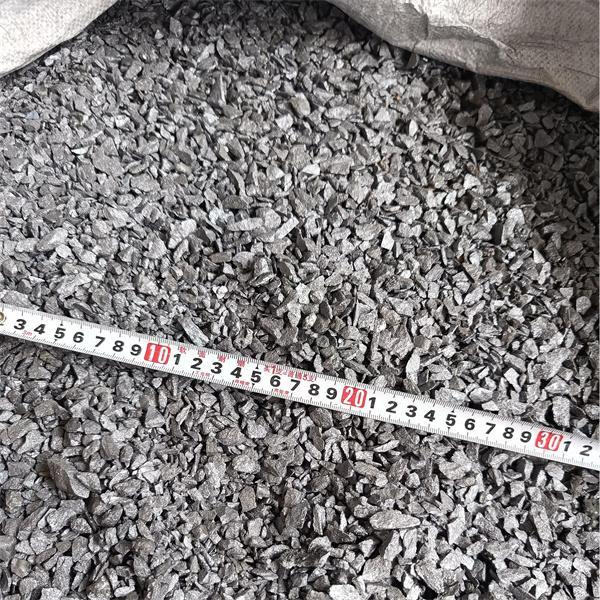

When you combine various metals to make a new one with unique properties, that’s called alloying. This is often done using Jinfengda ferro silicon lumps which strengthen the new metal. The ferro silicon granules from Jinfengda are high quality; for this reason it is a very popular mixing iron and steel materials.

Metal goods must be strong and dependable. Silicon ferro granules are one of the mean products which are one of the regular equipment. With Jinfengda ferro silicon powder, steel producers can produce very strong, and very high quality steel products. Whether you are talking about an auto part or a kitchen utensil, ferro silicon granules do wonders when it comes to enhancing metal items.

Foundries Foundries are facilities where metal is melted and formed. Ferro silicon lumps are commonly used by foundrymen to increase the tensile and yield scores of castings. They aid in the purification of the steel and stabilize the metal as it is cast. Jinfengda ferro silicon alloy are widely used by both foreign and domestic foundries.

We implement stringent quality control through in-house element testing and support third-party inspections (SGS, BV, AHK), ensuring our products meet international standards for purity and performance.

We offer personalized metallurgical solutions tailored to client needs, backed by a 1-hour response guarantee via multiple channels (WhatsApp, WeChat, Email) and dedicated problem-solving throughout the project lifecycle.

Our 120,000-square-meter factory is equipped with 26,300KVA alloy refining electric furnaces and 8 intermediate frequency furnaces, ensuring robust production capabilities for a variety of metallurgical products including Ferro Silicon and Low Carbon Ferro Chrome.

With over 20 years of export experience, we have successfully served markets in South Korea, Japan, Germany, Turkey, Russia, and beyond, providing timely delivery, strong logistics partnerships, and reliable after-sales support.