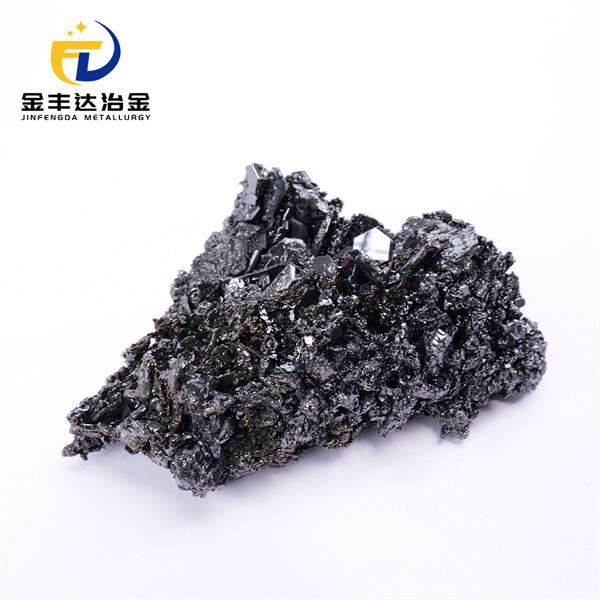

Silicon carbide is a hard material that is used to make different metals stronger. It has been used in a practice known as metallurgy, where the focus is on shaping and improving metals. Jinfengda is a firm that’s done a lot of work on how silicon carbide can be utilized in superior metal mixes.

Silicon carbide is an extremely hard material consisting of carbon and silicon. It is used for so much, such as in producing tools and beautiful jewellery. Metallurgical use the most application of the compound silicon carbide is that its used in metallurgy. Metallurgy is us working with metals to improve and to strengthen them. However, by blending in metal with black silicon carbide, to make the composite, we can achieve even more intense addition to the depth of field.

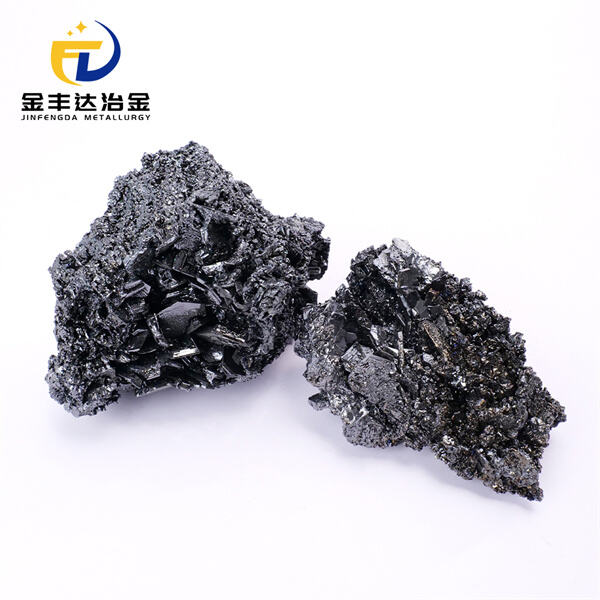

There are lots of reasons why Jinfengda silicon carbide is utilized in metallurgy. One reason is that it strengthens metals far beyond what they would be on their own. This allows us to construct longer lasting tools and machines. Another reason is that silicon carbide helps metals to withstand high temperatures, which is critical in many tasks. With silicon carbide, we can make better devices that can function at high power in tough situations.

When we mix silicon carbide with the metal, the metal behaves differently. The small silicon carbide particles are like little helpers along the metal, strengthening it. This ensures that products produced from them can endure more pressure and wear before breaking. It also aids the metal in warding off rust, which is what occurs when metal becomes aged and sullied. Inclusion of carborundum silicon carbide helps bring products into a longer life and superior working.

Silicon carbide is an exceptionally useful material in many respects. It can be mixed into steel to make it harder because harder is better for tools and machines. It can also be combined with aluminum to maximize its light weight and strength, which is ideal for stuff like airplanes and cars. Jinfengda's silicon carbide can also be used to make ceramics, which are also very strong and can withstand high temperatures. If we understand how to utilize silicon carbide in our products, we can improve them for lots of different tasks.”

With over 20 years of export experience, we have successfully served markets in South Korea, Japan, Germany, Turkey, Russia, and beyond, providing timely delivery, strong logistics partnerships, and reliable after-sales support.

We offer personalized metallurgical solutions tailored to client needs, backed by a 1-hour response guarantee via multiple channels (WhatsApp, WeChat, Email) and dedicated problem-solving throughout the project lifecycle.

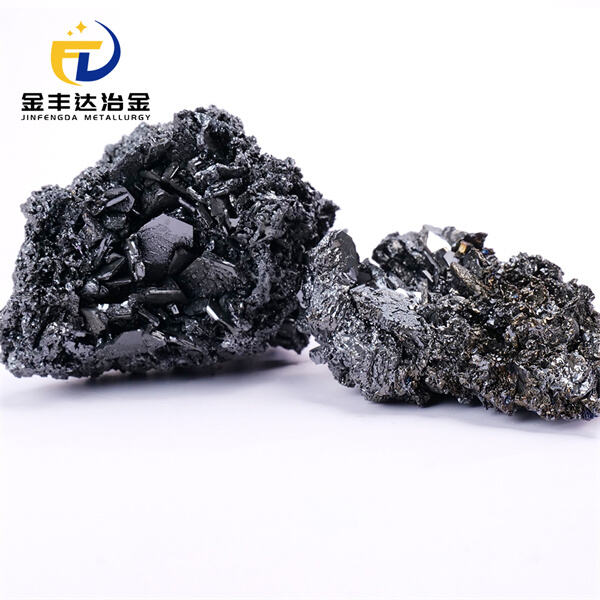

Our 120,000-square-meter factory is equipped with 26,300KVA alloy refining electric furnaces and 8 intermediate frequency furnaces, ensuring robust production capabilities for a variety of metallurgical products including Ferro Silicon and Low Carbon Ferro Chrome.

We implement stringent quality control through in-house element testing and support third-party inspections (SGS, BV, AHK), ensuring our products meet international standards for purity and performance.