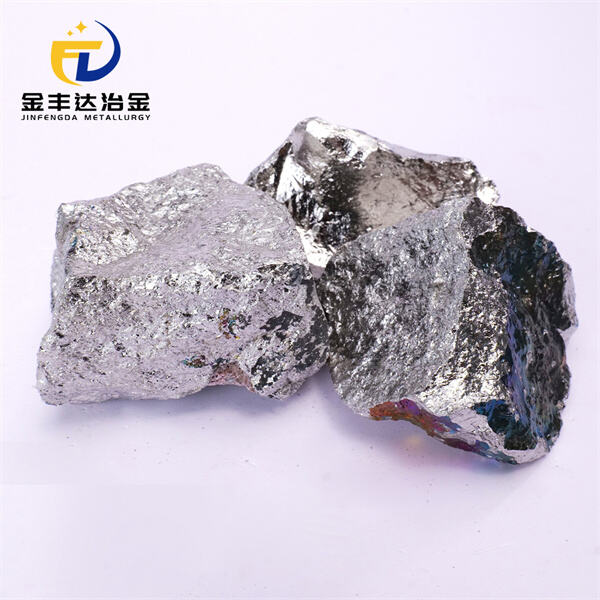

Carbon fero manganese is a material to creat steel. It is comprised of carbon, iron and manganese that are key ingredients in the production of quality steel.

Carbon ferro manganese is frequently employed in the steel industry to enhance steel and make it stronger and harder wearing. It promotes attributes in steel that help it withstand wear and tear.

However, in steel making sector, C Fe Mn is very important for producing good steel products. By adding carbon ferro manganese to steel, manufacturers are able to increase the hardness and strength of the metal. That’s useful in constructing things, machinery and other equipment that must be strong and durable.

Steel making with carbon ferro manganese has many advantages. One of the big advantages: It makes steel stronger and less likely to rust, a plus for heavy-duty work. It also makes steel more malleable, and less brittle, so it can be worked into different products. And carbon ferro manganese can help reduce the cost of producing steel overall, since it’s cheap and easy to get.

The manufacturing process for the product requires a certain degree of caution since it is carbon ferro manganese. - First, manganese ore, coke, and iron ore are combined in a furnace and heated to high temperatures. This causes the ingredients to melt, creating a liquid metal that can be poured into molds and allowed to cool and harden. The end product is carbon ferro manganese (also known as carbon manganese) which is used in making steel stronger.

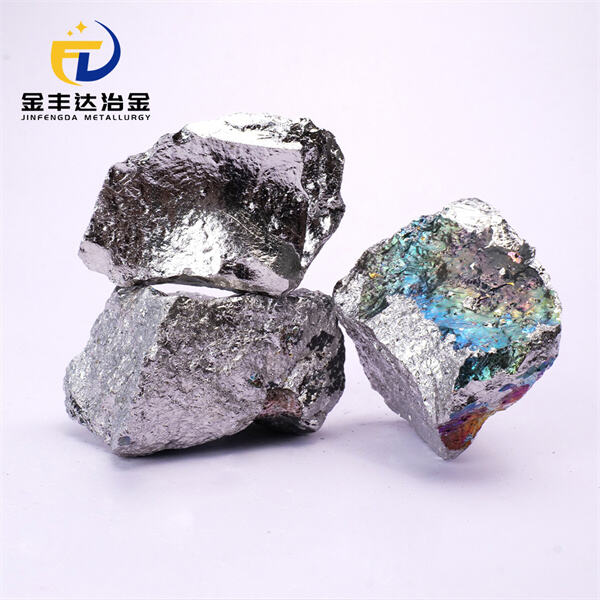

Types There are two primary-primary types of carbon ferro manganese: high-carbon and medium-carbon. For instance, ferro manganese HC has more carbon and helps make steel more hard and resistant to wear. These are commonly used to manufacture tools and machinery. Low-carbon ferro manganese is not as strong as ordinary carbon steel but as it’s a tough material and work-hardens it is usually used for construction, forestry, material handling and other applications where bending is required for welding.

Our 120,000-square-meter factory is equipped with 26,300KVA alloy refining electric furnaces and 8 intermediate frequency furnaces, ensuring robust production capabilities for a variety of metallurgical products including Ferro Silicon and Low Carbon Ferro Chrome.

With over 20 years of export experience, we have successfully served markets in South Korea, Japan, Germany, Turkey, Russia, and beyond, providing timely delivery, strong logistics partnerships, and reliable after-sales support.

We implement stringent quality control through in-house element testing and support third-party inspections (SGS, BV, AHK), ensuring our products meet international standards for purity and performance.

We offer personalized metallurgical solutions tailored to client needs, backed by a 1-hour response guarantee via multiple channels (WhatsApp, WeChat, Email) and dedicated problem-solving throughout the project lifecycle.