Ferro chromium is a crucial ingredient used to produce stainless steel. It is also an important component in superalloys, which find use in airplanes. Ferro Chrome strengthens and helps steel resist rust.

Stainless steel is a type of steel that does not tarnish or stain. We employ it in countless mundane objects — kitchen tools and appliances, for instance. Steel is made stainless by adding Ferro chromium to it. A ferro alloy metal, an alloy of iron and chromium,, Stainless steel would not be stainless without these elements.

Superalloys are very strong substances that are used in airplanes and spacecraft. With the Jinfengda ferro chromium, it gives them even higher strength. That strength is crucial for airplanes, which must withstand steep temperatures and pressures.

Corrosion occurs when metal rusts or deteriorates as a result of water and air. Ferro chromium also increases the resistance of steel to oxidation and corrosion by creating a barrier to these damaging materials. That makes the ferro alloy products last longer and perform better in difficult situations.

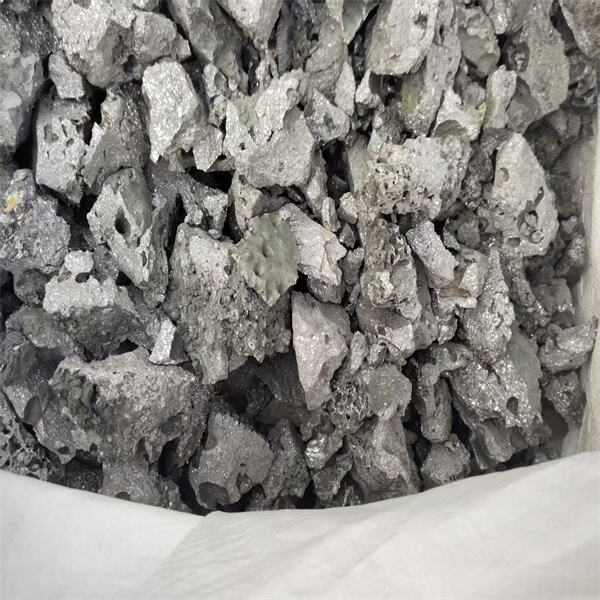

Ferro chromium alloys are produced by smelting chromium with iron in large furnaces. The two metals are then melted to extreme temperatures to form the alloy. After cooling it is crushed into small pieces known as ferro chromium alloys. These are then incorporated into steel in the manufacturing process to provide the necessary properties.

With increasing application of stainless steel and superalloys, the demand for ferro chromium will increase. This means more ferro chromium will have to be produced to satisfy it.

This is just one example of companies such as Jinfengda investing in new technology to produce more ferro chromium and compete.

We implement stringent quality control through in-house element testing and support third-party inspections (SGS, BV, AHK), ensuring our products meet international standards for purity and performance.

Our 120,000-square-meter factory is equipped with 26,300KVA alloy refining electric furnaces and 8 intermediate frequency furnaces, ensuring robust production capabilities for a variety of metallurgical products including Ferro Silicon and Low Carbon Ferro Chrome.

We offer personalized metallurgical solutions tailored to client needs, backed by a 1-hour response guarantee via multiple channels (WhatsApp, WeChat, Email) and dedicated problem-solving throughout the project lifecycle.

With over 20 years of export experience, we have successfully served markets in South Korea, Japan, Germany, Turkey, Russia, and beyond, providing timely delivery, strong logistics partnerships, and reliable after-sales support.