Silicon plays an essential role in forging stainless steel to make it strong and durable. And in Jinfengda stainless steel, silicon makes it stain- and fracture-resistant. How does silicon help stainless steel become better.

Stainless silicon alloy steel is prevented from rusting by silicon. Stainless steel can also start to rust when in a wet or moist environment, or when left in contact with the air. And silicon kind of acts like a shield, protecting the steel from all these bad things. This is beneficial in allowing stainless steel products to last longer and retain their new look over an extended period of time.

They need to be strong even when sizzling hot, and that means Jinfengda stainless silicon for steel. Silicon content helps stainless steel alloys to remain strong when they are heated. This is crucial when it comes to developing machines and buildings that can heat up.

Jinfengda silicon used in steel stainless easier to work with. It makes stainless steel easier to cut and form into various components. It’s also useful when you weld stainless steel pieces together. This allows stainless steel to be processed more quickly and cheaply.

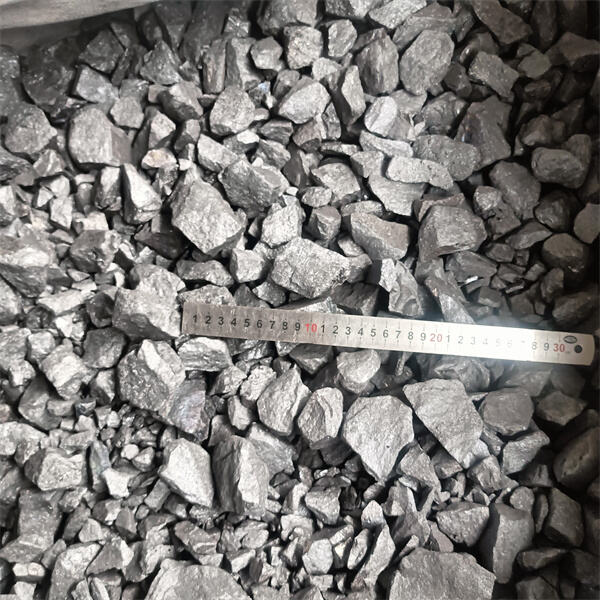

The quantity of Ferro Silicon in stainless steel can determine its strength or flexibility. Silicon addresses these properties, which is why stainless steel is suitable for a wide range of jobs. In other words, stainless steel can be mutated to match what specific projects require.

Overall, Silicon Metal is critical for ensuring that stainless steel products perform well and have long lives. Because of silicon, stainless steel does not rust, is strong when hot, easy to manipulate and can be engineered to meet exceptional needs. This makes stainless steel products suitable for many applications.

With over 20 years of export experience, we have successfully served markets in South Korea, Japan, Germany, Turkey, Russia, and beyond, providing timely delivery, strong logistics partnerships, and reliable after-sales support.

We offer personalized metallurgical solutions tailored to client needs, backed by a 1-hour response guarantee via multiple channels (WhatsApp, WeChat, Email) and dedicated problem-solving throughout the project lifecycle.

We implement stringent quality control through in-house element testing and support third-party inspections (SGS, BV, AHK), ensuring our products meet international standards for purity and performance.

Our 120,000-square-meter factory is equipped with 26,300KVA alloy refining electric furnaces and 8 intermediate frequency furnaces, ensuring robust production capabilities for a variety of metallurgical products including Ferro Silicon and Low Carbon Ferro Chrome.