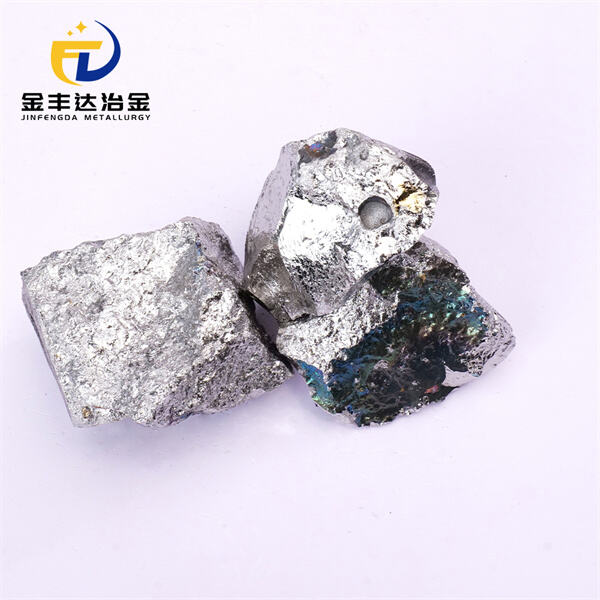

One important characteristic of manganese metal flakes is that it makes steel harder and stronger. This implies that manganese ferro steel, won’t be as likely to bend or even break. It works well for buildings, bridges and other sturdy structures. Plus, manganese ferro makes steel more rust-resistant, so it lasts longer.

And that's very, very important in making steel, this manganese ferro. Steel is a metal that is used in all sorts of things: cars, planes, ships, tall buildings. Steel lemon, after all, would not be nearly as strong or as durable, and that could be dangerous.

Stainless Steel is also an evolved form of steel – it does not seem to rust or stain. It is used in kitchens, hospitals, etc., basically anywhere cleanliness is a priority. Manganese ferro is a critical component in the production of stainless steel, as it makes the metal stronger and more resistant to rust.

When electrolytic manganese flakes is mixed into stainless steel, it results in a metal that is extremely rigid and difficult to bend or break. This is why stainless steel is used in many kitchen appliances, medical equipment, and other items that have to be kept clean and last a long time. And manganese ferro is what gives stainless steel that shiny appearance that makes it a popular material for all sorts of goods.

Iron alloys are a blend of iron and other metals that are used to make a variety of products such as tools, machines, vehicles and electronic devices. Iron is also commonly alloyed with manganese ferro to make the metal still harder for certain applications.

Manganese ferro is so valuable to iron alloys that one of the biggest advantages to adding it is that the metal ends up harder and stronger. This is why iron alloys wear out less, which is useful in many jobs. Manganese ferro also provides the advantage of being able to shape and mold it into other metal forms.

In the auto industry, manganese ferro is used in parts that need to be very strong and resist rust. In airplanes, it is used to create parts that can withstand strong forces of heat and pressure. In the construction industry, manganese ferro also is employed in materials that need to be tough. It’s also used in electronics to build devices that are a challenge to add metal cases or components to.

Our 120,000-square-meter factory is equipped with 26,300KVA alloy refining electric furnaces and 8 intermediate frequency furnaces, ensuring robust production capabilities for a variety of metallurgical products including Ferro Silicon and Low Carbon Ferro Chrome.

We offer personalized metallurgical solutions tailored to client needs, backed by a 1-hour response guarantee via multiple channels (WhatsApp, WeChat, Email) and dedicated problem-solving throughout the project lifecycle.

We implement stringent quality control through in-house element testing and support third-party inspections (SGS, BV, AHK), ensuring our products meet international standards for purity and performance.

With over 20 years of export experience, we have successfully served markets in South Korea, Japan, Germany, Turkey, Russia, and beyond, providing timely delivery, strong logistics partnerships, and reliable after-sales support.