Ever wonder how people in ancient times made tools, weapons, and lovely art objects out of metal? (One place where that skill is still practiced today is at the alloy carbon.) A trip to Jinfengda foundry forge allows you to step back in time and witness how blacksmiths use ancient methods to transform raw materials into art.

The moment you step into the Jinfengda best quality ferro chrome, you hear the clinking of metal being hammered and the heat from the forge. Talented blacksmiths work deliberately as they form the hot metal into various forms. I love watching them use their special tools to make all these beautiful pieces right before your eyes.

There’s great interest in the foundry forge process where raw material is turned into art.” The metal is first melted in a furnace. Next the blacksmith pours the hot liquid metal into molds, or he (or she!) works it by hand with anvils and hammers. With each stroke of the hammer, the metal changes shape and forms into a work of art or a useful tool.

At Jinfengda foundry forge, you will discover the significant history of metal melting. Blacksmithing has been taught by master to apprentice for many years. If you are visiting a foundry forge, you get to see this craft in action, as well as feel linked to a tradition which has endured over centuries.

When you walk the floor of the Jinfengda foundry forge you get all the sights and sounds of a metal shop in action. The clang of hammers on an anvils and the roar of the furnace are audible and the red-hot metal glimmers out. You will feel the heat penetrate your skin and smell the burning metal just by watching the blacksmiths. It's a fun experience to make you appreciate the art of metalworking.

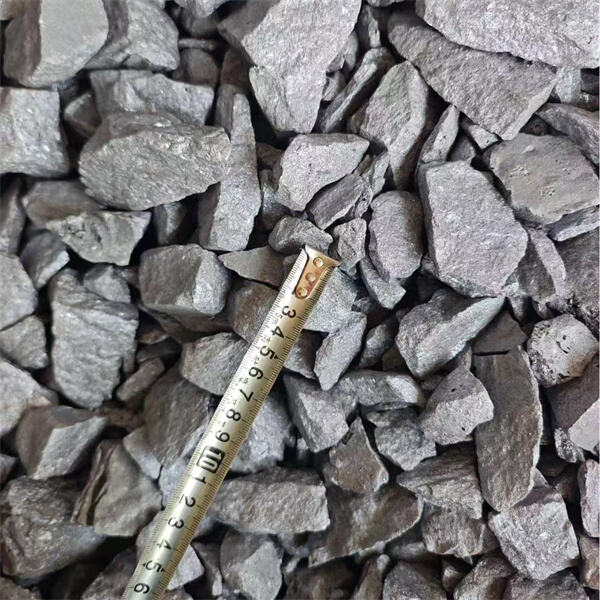

Our 120,000-square-meter factory is equipped with 26,300KVA alloy refining electric furnaces and 8 intermediate frequency furnaces, ensuring robust production capabilities for a variety of metallurgical products including Ferro Silicon and Low Carbon Ferro Chrome.

We implement stringent quality control through in-house element testing and support third-party inspections (SGS, BV, AHK), ensuring our products meet international standards for purity and performance.

With over 20 years of export experience, we have successfully served markets in South Korea, Japan, Germany, Turkey, Russia, and beyond, providing timely delivery, strong logistics partnerships, and reliable after-sales support.

We offer personalized metallurgical solutions tailored to client needs, backed by a 1-hour response guarantee via multiple channels (WhatsApp, WeChat, Email) and dedicated problem-solving throughout the project lifecycle.