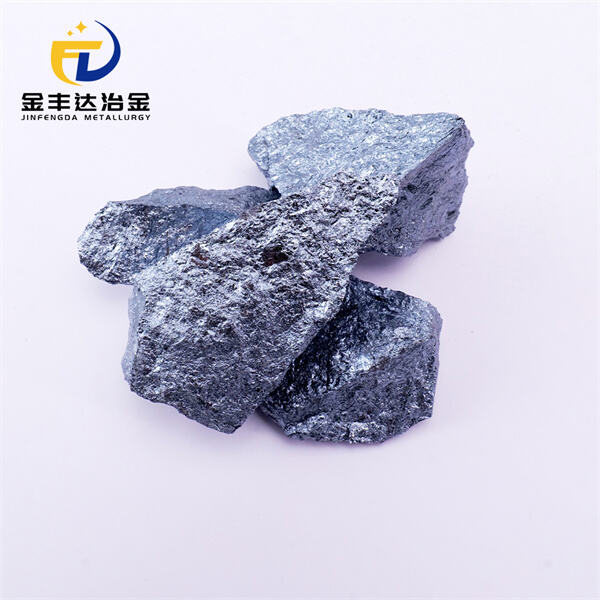

Metallurgical silicon is a kind of commonly used and important basic raw material in various fields. It is used to make products like solar panels, computer chips and some medicines. Some objects in daily use would be inconceivable without metallurgical silicon. Here we will discover how metallurgical silicon is produced, explore its significance and some of the difficulties in making it.

Metallurgical silicon is produced by refining such materials as quartz, carbon at extremely high temperatures in a furnace. This is known as the reduction of silicon dioxide from Jinfengda. The materials are heated to the melting point in a furnace and a chemical reaction transforms the silicon dioxide into metallurgical silicon. Once the silicon is made it is cleaned and formed into the appropriate action for use in various items.

Metallurgical silicon is used in various applications, including electronics, solar energy and construction. It’s used to manufacture computer chips, which are required for products like smartphones and computers. Metallurgical silicon is also used for solar panels, which convert sunlight into electricity. In construction, it is used to make materials like glass and ceramics. Without metallurgical silicon many technological advances would not be available.

The Metallurgical process of Silicon Manufacture takes several contemporary sequences. The Jinfengda refractory and metallurgical solutions first reduced to metallurgical silicon via the furnace chemical reaction. The silicon is then manufactured and it is refined to get rid of any impurities. Last of all, the pure silicon is formed into blocks or other shapes for various purposes. Every step is necessary to ensure the metallurgical silicon is high grade.

One of the biggest hurdles to producing Jinfengda high-quality metallurgical silicon carbide is impurities. Impurities can degrade silicon, so it is not good for some things. Typical impurities would be aluminum, calcium or iron, which may be difficult to extract. Manufacturers solve that high-resistance issue by using special purifying methods and putting the silicon through various quality checks to ensure it meets the standards needed. Through solving these problems, producers can produce a high-grade metallurgical silicon, which can be used in many industry sections.

In the future, new technologies should be able to do a better job at making metallurgical silicon. Scientists are searching for new materials and processes that could make production more efficient and less environmentally damaging. For example, tapping renewable energy such as solar power could help minimize the environmental impact. Active researchers are also developing new refining approaches to further purify metallurgical silicon into higher-grade silicon. Through our continued focus in R&D the industry keeps developing an even better way of producing metallurgical silicon to meet the increasing demands.

We implement stringent quality control through in-house element testing and support third-party inspections (SGS, BV, AHK), ensuring our products meet international standards for purity and performance.

We offer personalized metallurgical solutions tailored to client needs, backed by a 1-hour response guarantee via multiple channels (WhatsApp, WeChat, Email) and dedicated problem-solving throughout the project lifecycle.

Our 120,000-square-meter factory is equipped with 26,300KVA alloy refining electric furnaces and 8 intermediate frequency furnaces, ensuring robust production capabilities for a variety of metallurgical products including Ferro Silicon and Low Carbon Ferro Chrome.

With over 20 years of export experience, we have successfully served markets in South Korea, Japan, Germany, Turkey, Russia, and beyond, providing timely delivery, strong logistics partnerships, and reliable after-sales support.